Airlaid for sustainable food packaging

In a world shifting towards sustainability, the packaging industry is under increasing pressure to reduce its carbon footprint and waste, and legislation to remove plastic from packaging may very well be underway. Airlaid technology presents a groundbreaking solution to this problem, offering an environmentally friendly alternative to traditional paper, cardboard and even plastic packaging.

CAMPEN has successfully developed airlaid machinery which makes it possible to incorporate waste fibers or other natural, fiber-based waste products into the airlaid process to create a spectrum of high-quality, 100% natural and compostable packaging options, including fruit and vegetable trays.

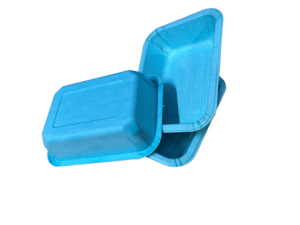

Sustainable food trays made in the airlaid process with either 100% fluff pulp or straw fibers and cardboard scrap material combined with fluff pulp

What is airlaid?

Airlaid represents a groundbreaking nonwoven fabric technology. Instead of weaving or knitting yarns together, the airlaid technology disperses fibers through an airstream, compacting them onto a conveyor with air pressure to form a web-like structure. This unique process produces airlaid material with exceptional absorbency and robust tensile strength. While its applications have spanned baby diapers to filtration systems, its qualities make it a promising contender as an alternative in the packaging world, especially for those seeking sustainable replacements for traditional cardboard or plastic materials.

Why choose airlaid for food packaging?

Compostable and Biodegradable

Airlaid technology can produce packaging made from 100% natural fibers, such as cellulose, straw or industrial waste fractions, e.g. cardboard scraps. These materials are not only plastic-free, but also 100% compostable, capable of breaking down naturally without harming the environment.

Efficient and Eco-Friendly Production

The airlaid process diverges from traditional wet processes used in paper and cardboard production that require significant amounts of water. Airlaid technology uses only process air to transport and handle fibers, thus reducing energy consumption significantly. Our calculations show that the airlaid process uses 10 times less energy and 100 times less water than traditional wet processes.

Enhanced Properties Through Coatings

To add functional properties like water repellency or gas tightness, CAMPEN collaborates with specialized coating manufacturers. These coatings, like the base materials, are entirely compostable and natural, ensuring that the packaging remains eco-friendly throughout its life cycle. Coatings are available as spray coating or film.

Circular Economy and Cost Savings

Companies can repurpose waste fibers in new products, thereby contributing to a circular economy. This not only minimizes waste, but also translates to substantial cost savings in waste disposal.

In-House R&D and Testing Facility

CAMPEN goes beyond just providing machinery; we offer a technical partnership, including consultation services, to guide you in producing the optimal airlaid material for your products. We even house an R&D center equipped with a pilot line, where clients can test technology and develop their packaging solutions.

Applications Beyond Food Packaging

While the focus here is on food packaging, it is essential to recognize that airlaid technology is not confined to this sector. It has wide-ranging applications in everyday products like napkins, diapers, sanitary napkins, meat packaging and wet wipes.

Compostable airlaid trays

CAMPEN has developed a process, currently patent pending, where airlaid material can be converted into biodegradable trays made from 100% natural materials, such as pure cellulose, or a balanced blend of cellulose and natural fibers, such as straw.

Entirely devoid of plastic, these trays are 100% home compostable, ideal for fruit and vegetable packaging. When paired with a 100% natural coating, where CAMPEN offers several coating methods, they effectively repel water.

Upcycled food trays

In addition to above-mentioned 100% natural fibers and wood pulp, CAMPEN has also successfully developed processes where recycled cardboard is merged seamlessly with fluff pulp in CAMPEN’s airlaid machinery. This results in high-quality airlaid material, which can also be made into airlaid trays.

By using waste fibers from e.g. internal cardboard production, it not only presents an economical alternative to discarding excess cardboard or waste fibers, but also replaces traditional plastic and cardboard packaging with greener substitutes.

Example of trays made by forming an airlaid nonwoven sheet into trays with nothing but heat and pressure

Examples of sustainable food packaging made from airlaid

- Biodegradable food trays

- Absorbent pads for meat, poultry and seafood

- Fast food or takeaway packaging

- Drink coasters

- – and much more!

Growing consumer demand for sustainable packaging

With the EU Directive 2025 on the way, there is a growing emphasis on eco-friendly practices across industries, particularly in packaging.

Airlaid is a viable and future-proof alternative to plastic and cardboard packaging, which dramatically cuts down on both water and energy use compared to traditional wetlaid processes. This factor alone makes it a standout option in the face of the new directive’s focus on reducing environmental impact through smarter resource use.

Moreover, with our unique technology, airlaid’s functional adaptability is remarkable. It can be made water-resistant with sustainable coatings and adjusted for stiffness, comparable to cardboard. This versatility, combined with its biodegradability, positions airlaid as a comprehensive, environmentally responsible alternative.

In today’s market, where both consumers and regulations are increasingly pushing for greener solutions, airlaid presents an opportunity not just to meet standards, but to embrace forward-thinking, sustainable innovation.

We invite you to explore this technology as a sustainable, cost-effective and high-quality solution for your packaging requirements. Contact us here to book your exclusive visit to our test center.