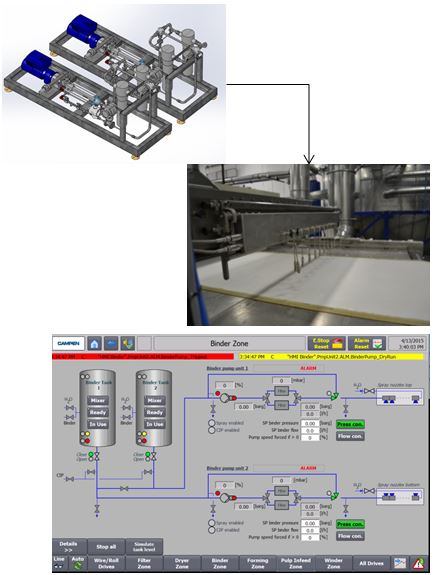

BATCH MIXING SYSTEM FOR BINDER

Preparation and mixing of binder, additives and water in a separate mixing tank with subsequent feeding to a pumping unit and a spray application unit.

The modern CAMPEN mixer can also be used to mix the binder.

CAMPEN mixer for foaming of natural / synthetic latex or adhesive

Batch mixing system for binder – liquid

- Pumping unit with an AC driven mono pump with variable speed regulation

- Flow indication with readout of current flow

- Pressure measuring with readout on the overall control panel

- The pump output is automatically controlled to reach a certain pressure in order to give a uniform spray pattern on the fabric

- Duplex filter unit, one for each pump, with differential pressure switch with alarm. Filter size: 50 microns

- With automatic or manual changeover

- In case of a short line stop, the pump will automatically run at minimum capacity in a bypass loop to prevent clogging of binder inside the pump

- Manually operated CIP system

- Capacity: up to 10,000 l/hour per batch