Airlaid Turnkey Systems

CAMPEN supplies complete airlaid turnkey systems and airlaid machinery to most product areas of the nonwoven industry. We at CAMPEN can adapt and adjust airlaid machinery to our clients’ specific production set-up and ensure a flexible, efficient and energy-saving production.

Our experienced engineers and technical staff are also constantly finding new ways to optimize the different production processes with our machinery.

Below, three examples of airlaid turnkey lines based on the final product.

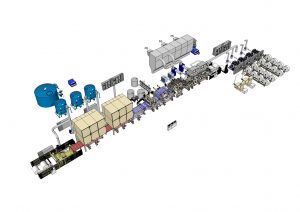

NEW! TBAL airlaid absorbent core production line

This newly developed line is designed for the production of absorbent core, meat / underpad absorbers, wound care products etc.

- High production/h

- Laminating with nonwovens, film etc.

- Less use of energy

- Homogeneous mix of man-made fibers and SAP – SAF with pulp in the forming process

- Reclaim of selvedge trim from automatic winder – low waste level during production

- In-line slitting with roll diameter up to 1500 mm

- Roll wrapping with stretch film, before removal of the roll from the winder

- Less space needed and no need of special building modifications for the line

- Less need of process air/kg airlaid paper

- Less maintenance

- Easy to operate

- Less investment/ton airlaid paper

- Max. working width: 1000 mm

Contact us to learn more about this line.

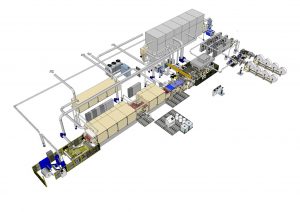

Airlaid line for disposable wipes, napkins, absorbent core, medical and food applications

The BBAL or TBAL line is the optimal solution for producing disposable wipes, napkins, absorbent cores, medical and food applications.

Airlaid processes in the line:

- Fiberization

- Forming

- Bonding

- Drying

- Winding and packaging

Contact us to learn more about this line.

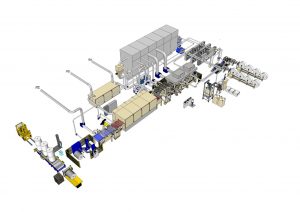

Drylaid / airlaid spunlace turnkey system – line for disposable, flushable, dispersible and biodegradable wipes and nonwovens

This line combines airlaid with the spunlacing process to produce a nonwoven for wet and dry wipes which is up to 100% disposable and biodegradable. This nonwoven is characterized by extremely soft wipes with a very high tensile elongation making this raw material a sustainable product without compromising on quality.

Airlaid processes in the line:

- Carding

- Unwinding

- Fiberization

- Forming

- Spunlacing

- Drying

- Winding and packaging

Contact us to learn more about this line.