Noise-reduced and cost-effective Hammer Mill / Defibrator

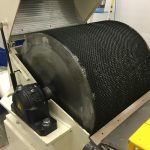

The hammer mill, also known as defibrator, separates compressed rolls of fluff pulp into individual, loose fibers, which are then transported to the web forming system.

100% fiberization and zero nits

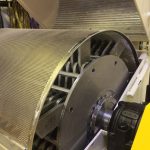

CAMPEN offers two basic types of defibrators: the conventional hammer mill using the traditional swinging hammers and the new CAMPEN hammer mill using a fixed beater rotor. Both solutions result in high-quality fluff with up to 100% fiberization and zero nits. The hammer mill can handle several different pulp types with the same high quality and fiberization result.

Low energy consumption and low noise level fiberization

The CAMPEN hammer mill has a unique design, which lowers the general energy consumption compared to existing hammer mill solutions. To further reduce the energy consumption, the new CAMPEN defibrator has a highly energy-efficient, fixed beater rotor, and it reduces the noise level significantly. Furthermore, it ensures a cost-efficient fiberization process and minimizes the practical challenges concerning noise reduction.

High flexibility hammer mill / defibrator

The CAMPEN hammer mill can easily be adapted to your specific production set-up. The hammer mill / defibrator can handle a variety of pulp types, and it is integrable with all types of airlaid systems. Furthermore, the defibrator has an exchangeable beater and screen design for different pulp grades. This makes it quick and easy to adapt the mill to different kinds of pulp, ensuring a flexible and cost-efficient fiberization process.

CAMPEN also offers complete airlaid turnkey systems, where the hammer mill is an integrated part of the solution.

- Beater rotor or swinging hammers

- Direct or belt drive

- Single layer or double layer pulp feeding

- Airlaid fiber forming section

- Top inlet for fiber reclaim purpose and fiberization process

Type:

HM-05, HM-10, HM-20, HM-25, HM-40

Widths:

127, 254, 508, 635, 1016 mm

Pulp types:

Treated, semi-treated and untreated pulp

Elements:

Automatic roll change system

Non-blocking pulp feeding system

Hammer (beater rotor or swinging hammers)

Exchangeable screens

Air suction