Airlaid paper in packaging – a sustainable alternative

CAMPEN has successfully developed a process and technology allowing waste fibers and other naturally derived, fiber-based waste to be utilized in the airlaid process. This leads to the creation of entirely natural and compostable packaging solutions. Our technology can be used to further pave the way for more sustainable packaging manufacturing and circular economy in packaging.

What is airlaid paper?

Airlaid is a nonwoven textile, primarily composed of cellulose fibers, commonly referred to as fluff pulp. These fibers are formed into a web through the drylaid process, using air and pressure and resulting in a nonwoven fabric.

This material stands out from conventional paper in its unique attributes: it is notably bulkier, retains softness, and remarkably, maintains strength even when wet.

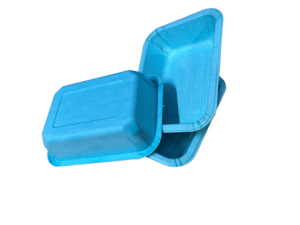

Sustainable food trays made in the airlaid process with either 100% fluff pulp or straw fibers and cardboard scrap material combined with fluff pulp

Sustainable production process

While wetlaid processes, which are used to produce paper and cardboard, are heavily reliant on water, the airlaid method takes a different path. It predominantly uses air for transporting and handling fibers, thereby significantly reducing the use of water and energy in the process.

In this way, the airlaid manufacturing emerges as a greener alternative to the conventional wetlaid process.

3 reasons why you should produce airlaid paper for packaging

1. The environment

The airlaid process is much more environmentally friendly than the wetlaid process used for cardboard and similar packaging. It uses no water and much less energy.

2. Upcycling

You have the possibility to upcycle fiber-based materials, e.g. excess cardboard from your production, and make them into a wide variety of products.

3. Variety

With one airlaid line, you have the ability to produce a wide variety of products with varying abilities and stiffness.

The rising role of airlaid in packaging

Airlaid technology is no stranger to everyday products, finding its place in items ranging from napkins and diapers to tablecloths and sanitary products.

With the gradual phasing out of plastic from the packaging sector, there is a growing inclination among companies to explore airlaid and its accompanying dry forming techniques for sustainable alternatives.

The advancements in our airlaid machinery and technology now cater to an array of fibers, encompassing everything from traditional wood pulp to waste fibers originating from packaging industries.

Biodegradable trays

CAMPEN has pioneered a groundbreaking process, which is currently patent pending, to transform airlaid material into biodegradable trays. The trays can be crafted from 100% natural materials, such as pure cellulose, a blend of cellulose and natural fibers or even waste fibers, such as those from internal cardboard production.

These plastic-free trays are entirely home compostable, making them the perfect choice for packaging fruits and vegetables. The trays can be coated in various ways with 100% natural coating to make them hydrophobic.

Example of trays made by dry moulding an airlaid nonwoven sheet

Airlaid test facility in Denmark

CAMPEN welcomes its customers at their airlaid testing facility. Available for rent, this space encourages exploration of novel products, fiber mixtures and other innovative applications, furthering product development ambitions under absolute confidentiality.

The process of developing food trays is developed to offer our customers valuable insight into how airlaid technology can be used for packaging, and the process is also available for sale. In our test facility, customers can develop their own food trays, either with our tools or bring their own tools.

Contact our Senior Airlaid Specialist to talk about how airlaid paper can be applied in your production or to test your products at the airlaid test center.