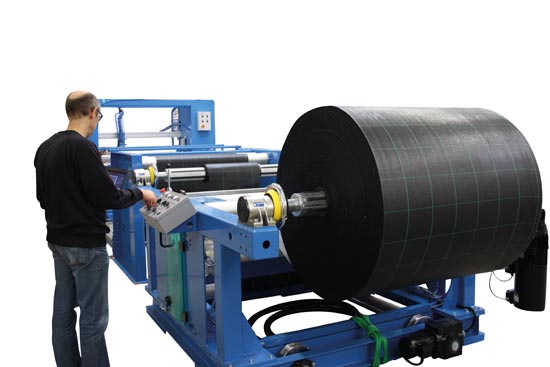

Center unwinder

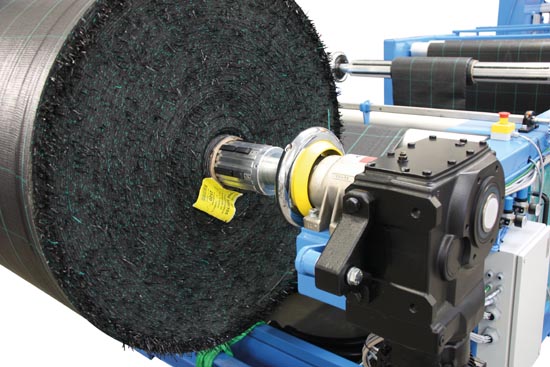

A center unwinder is very often used where the roll to be unwound is wound on a plastic, steel or cardboard tube, and by means of an expansion shaft it is possible to transfer the force from the drive motor to the roll itself.

Speed and tension are adjusted by means of an AC drive and controlled with a feedback signal from a dancing roller or a load cell in order to maintain a constant tension even with high dynamic unwinding systems.

Off-line converting

For off-line converting from mother roll to small roll, it is a condition that the mother roll is wound hard enough to withstand the dynamic forces coming from accelerating and decelerating the winding machine.

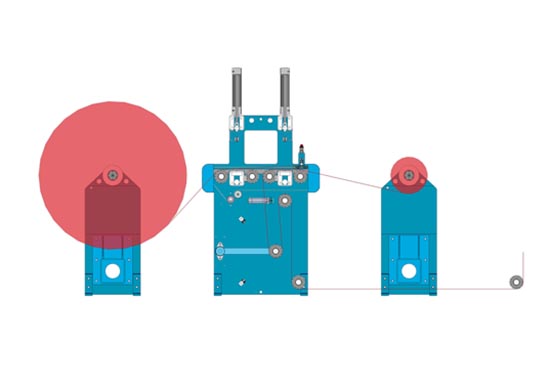

Single or double unwinding position

The center unwinder can be made with a single or double unwinding position, where the double unwinding system will minimize the stop time during roll change.

Splicing

Splicing of the fabric can be made by means of adhesive tape, sewing or heat splicing, and for in-line operation it can be combined with an accumulator.