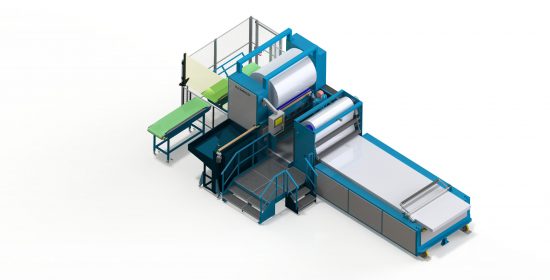

Surface winder

Surface winders are designed to handle in-line slitting and winding of a wide range of fabrics, such as nonwovens, textiles, roofing membranes, airlaid etc. Surface winders are typically used for in-line winding at low to moderate line speeds.

CAMPEN offers a full range of winders, ranging from simple, manual types to fully automatic solutions including feeding of cardboard tubes, cross cutting and automatic roll change.

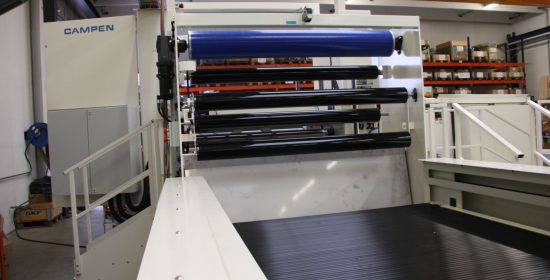

Twin roller surface winder

The most common type of surface winder is the twin roller surface winder with individual drives combined with a driven roller shortly before the winding rollers. With this combination you can adjust the roll compression by adjusting the web tension coming into the winder and adjusting the differential speed of the winding rollers.

Whether a top rider roller is needed or not, is very often depending on the size and weight of the core, if winding is in full width or with multiple slitting and depending on the product to be wound.

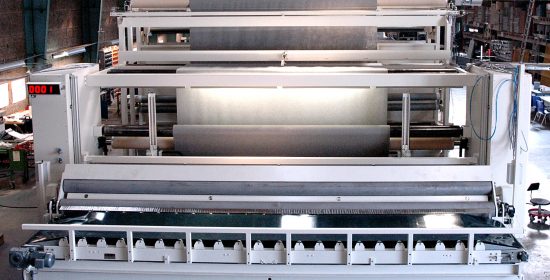

Surface winding of sensitive fabrics

For bulky or high loft and sensitive fabrics we also make solutions where the side mandrels are programmed to lift the core as a function of the roll length. As a result, you will get a final roll with exactly the diameter and softness you have selected.

Surface winder with accumulator

The roll change at a surface winder will always result in a short stop of the winder, hence a kind of accumulator or buffer is needed. CAMPEN offers different types, such as roller accumulator filling from the top, roller accumulator filling from the bottom or belt accumulator with variable accumulation factor, the latter of which is mainly used for sensitive nonwovens where low tension is required.

Learn more about our range of accumulators

Contact us to hear which type of surface winder fits your product and production type